"Our vision is to have printers on every continent," said Lennard Stoever, joint founder of Zellerfeld R&D. "Transport will then become superfluous and we can establish a circular economy in the respective country. Our shoes are fully recyclable." Zellerfeld now aims to build a factory in Austin, Texas where about 50 per cent of the shoes will be produced by 2,000 printers and the remainder by 200 printers in Hamburg. Founded in 2019, the company now offers a niche product as the shoes are only printed when customers scan their feet with a mobile phone. This results in waterproof, breathable, customised, laceless shoes in a quirky shape.

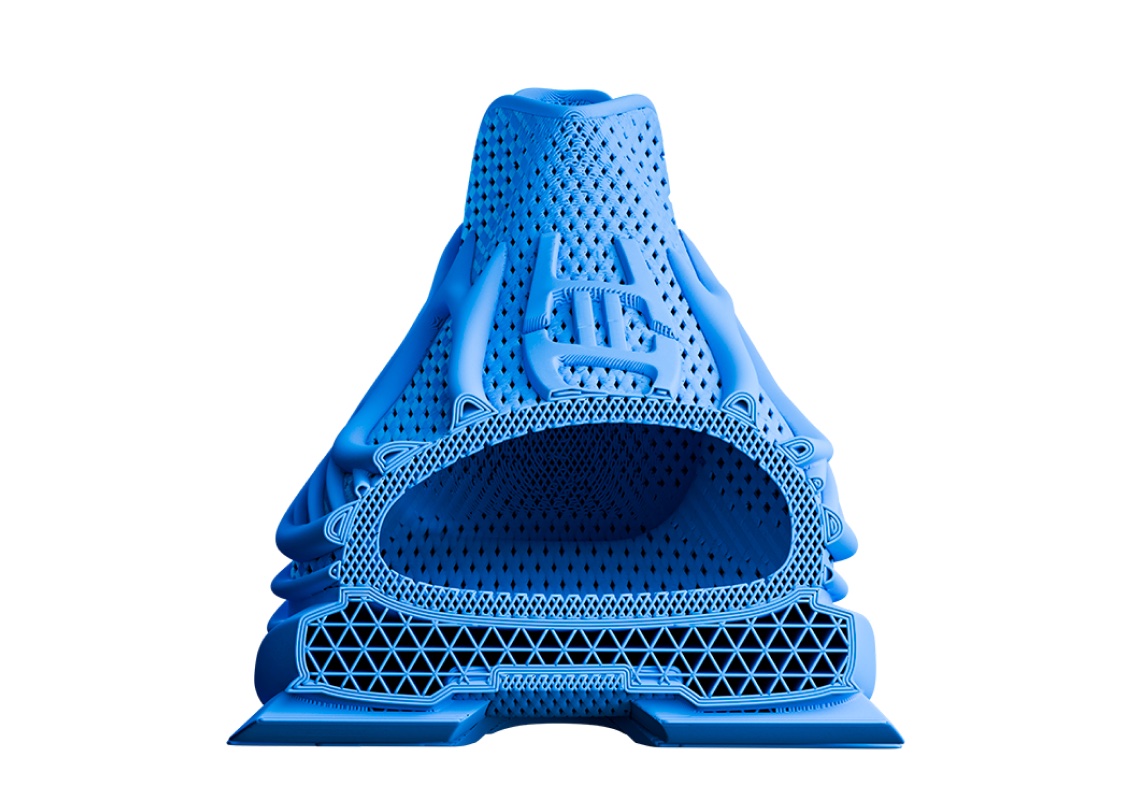

Stars such as Lewis Hamilton, Cro and Justin Bieber now wear 3D printed shoes by Zellerfeld R&D based in Hamburg-Stellingen. Nike is also working with the startup, which is now a global leader of digital shoe printing. A research project backed by IFB Hamburg helped to develop production and make Zellerfeld more economical.

"A printer on every continent"

Platform give creators freedom to design

"Unlike the traditional shoe industry, which produces standardised, mass-market goods, we produce sustainably and individually. We see ourselves as a platform that gives creators the freedom to design. Anyone can design their shoes that often look entirely different from what you're used to," Stoever pointed out. The customised shoes cost around USD 200 per pair and are comparatively cheaper than bespoke products. The designers set the price and the shoes are set to become even more affordable and accessible to a wider target group.

A shoe in less than 24 hours

The shoes are produced in layers. Starting with the heel, the entire shoe is 3D-printed in one piece using flexible plastic. Depending on the size, this involves up to 5,000 layer lines, and initially took over 100 hours. "We are now down to 36 hours, and will soon be down to less than 24," said Stoever. Errors that occur during printing lead to around 25 per cent of shoes being rejected, which is proving a hurdle. The aim is to identify errors during printing and to correct them without stopping the printer. Zellerfeld collaborated with the Fraunhofer Institute for Additive Production Technologies (IAPT) on the research project. The scientists improved the sensor technology, while Zellerfeld's experts optimised machine learning.

Funding from IFB Hamburg

"The project was very successful and the error rate has been reduced," Stoever stressed. IFB Hamburg provided nearly EUR 1 million funds as part of the Profi Transfer. The scheme provides grants of up to EUR 1 million for companies of all sizes and sectors that want to undertake novel projects with universities or research institutions in Hamburg. Zellerfeld received 45 per cent of the funds needed and 100 per cent from Fraunhofer IAPT. Zellerfeld is now printing the Air Max 1000 for Nike and is also making inroads into high fashion. The company employs 50 staff in Hamburg and produces 40,000 pairs of 3D printed shoes at the moment. Hopes are now high that one million pairs of shoes can be produced by 2028 or earlier.

mm/pb

Sources and further information

IFB Hamburg

The Hamburgische Investitions- und Förderbank (IFB Hamburg) is the main development bank in Hamburg. It focuses on housing and urban development, the economy, innovation and the environment. IFB Hamburg provides loans, subsidies, equity investments and security for investment projects in Hamburg on behalf of the state.

More

Similar articles

Future Hamburg Talk meets Heiko Milde, IFB Innovationsstarter

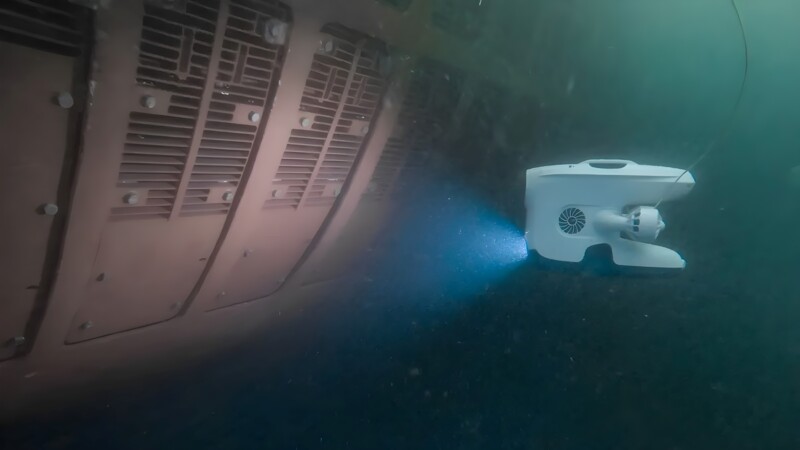

AI and drones to help inspect ships' hulls