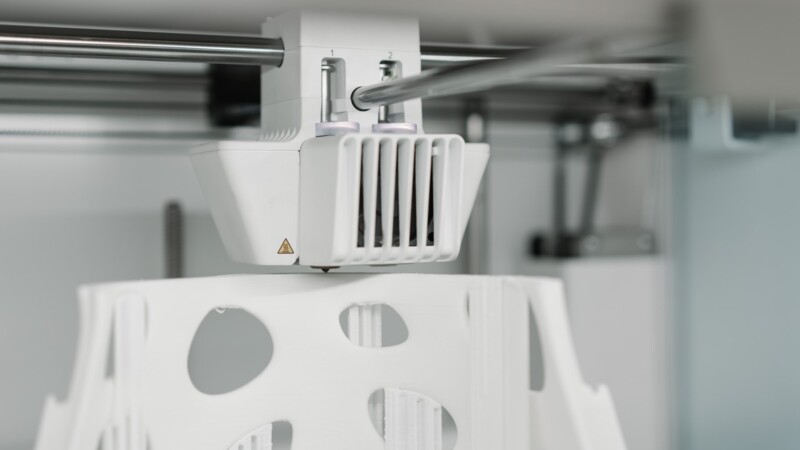

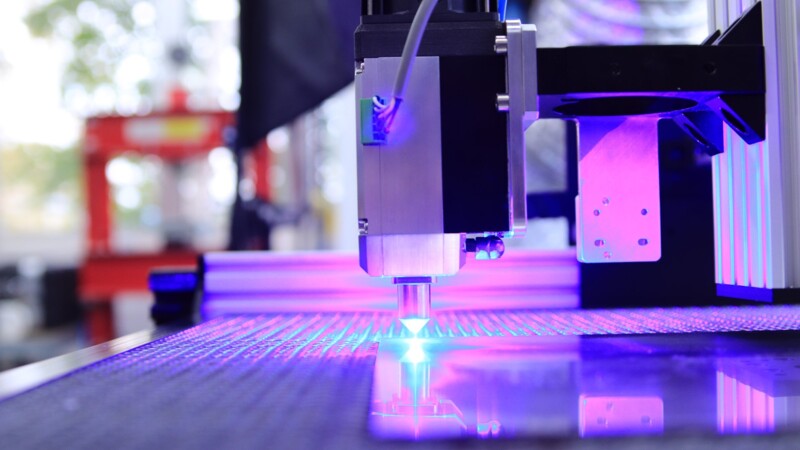

"We want to teach skills in the mobile production workshop, so that SMEs can identify potential for innovation and realise it themselves with new, digital production technologies," said Jürgen Glaser, project manager. Employees learn how to use modern technologies such as 3D printing and laser cutting n hands-on workshops and are encouraged to develop their own production methods. The truck is 13 metres in length and is currently in use at Scholz Mechanik where gripper components for robots are manufactured.

Companies across the city and the Hamburg Metropolitan Region now have even more access to state-of-the-art digital production machines thanks to the Open Lab Mobile truck operated by Süderelbe AG, which Melanie Leonhard, Senator for Economics, visited Wednesday (October 2, 2024). The mobile workshop is equipped with a CNC milling machine, 3D printer and laser cutter among other tools.

Springboard for companies

Potential for Hamburg's economy

"The Open Lab Mobile project has tangible benefits for companies," said Leonhard. "The offer is brought to you Try it out and develop customised solutions for your company together. "As part of the Fab City initiative, this is great support for more effective local production and holds great potential for sustainability. The scheme targets companies, start-ups as well as educational institutions across the Hamburg Metropolitan Region. "The cutting-edge manufacturing technologies of 3D printing offer innovative solutions. That boosts the innovative power of companies and the entire economy," Leonhard stressed. The Open Lab Mobile is part of the dtec.bw project Fab City, the Bundeswehr Centre for Digitalisation and Technology Research and is funded by Next Generation EU.

fw/mm/pb

Sources and further information

More

Similar articles

Fab City Hamburg e. V. to focus on digital local production

Pop-up Circular Hub to reopen in central Hamburg

Winners of Fab City's Maker Challenge start prototype phase