To counter the mounds of waste and to send recycling rates soaring, the EU has adopted all kinds of measures. Plastic, however, has advantages as it is lightweight, hygienic, relatively cheap and durable. But, ideally plastics should not be produced at all. Several start-ups in Hamburg are researching environment-friendly alternatives. The following are just some examples.

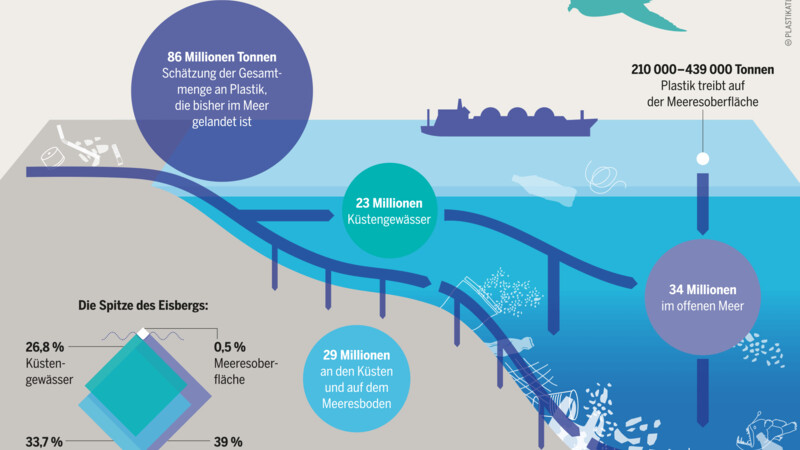

Plastic caps or lids on bottled drinks must be firmly attached to containers in future, according to an EU regulation effective since Wednesday (July 3, 2024). Loose caps are one of the ten types of plastic waste that wash up most frequently on beaches across the EU. "By 2030, all plastic packaging on the EU market should be reusable or cost-effectively recyclable", according to the EU Plastics Strategy. To drive up recycling rates, non-recyclable materials are now banned from packaging. Around 150,000 to 500,000 tonnes of plastic waste ends up in the sea every year. and less than 30 per cent of the 25.8 million tonnes plastic waste produced annually in Europe is recycled, according to the European Commission.

Environment-friendly business ideas from Hamburg

Camm Solutions & Gooden

Camm Solutions, for instance, has come up with a new type of water-soluble, biodegradable plastic and recently launched a microplastic-free beaker. Another start-up named Gooden has come up with plant-based, fully compostable sportswear. Their tank tops and T-shirts are made from seacell, a blend of wood fibre and seaweed that contains vitamins, trace elements, amino acids and minerals that are released into the skin through the fibres. The biological fibres in turn reduce the number of pollutants in the environment, unlike synthetic fibres e.g., polyester that are common in sportswear. Although polyester is lightweight, durable and dries quickly, tiny microplastic particles dissolve during washing and are released into the environment in wastewater. Sewage treatment plants cannot filter all of the particles and fibres between one and five micrometres in size out of the water. Unfortunately, they eventually enter the seafood chain and end up on our dinner plates.

Runamics & Recyclabs

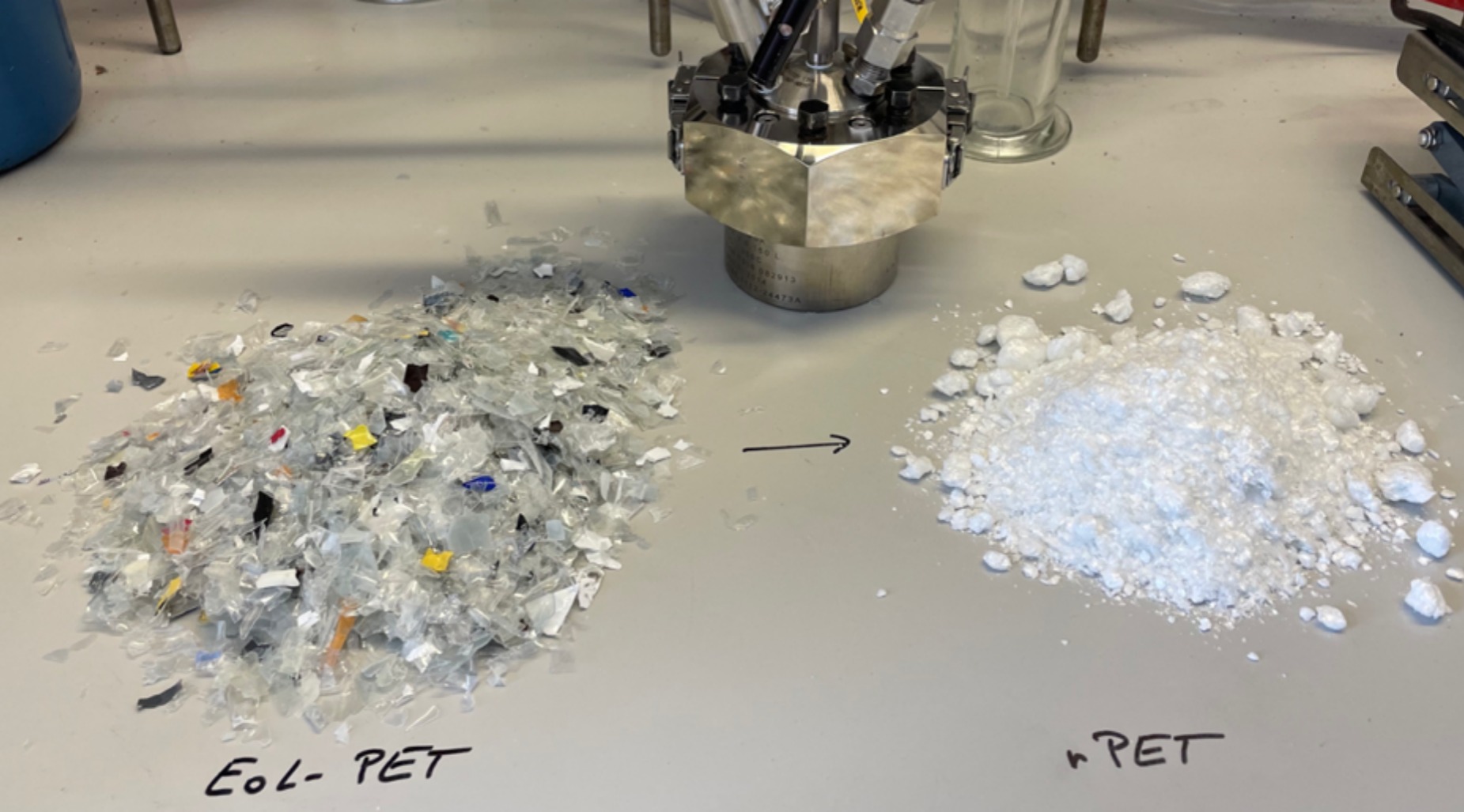

The Hamburg-based Runamics also makes sportswear from biodegradable fibres and focuses on circular production along the lines of the cradle-to-cradle concept developed by EPEA founder Professor Michael Braungart. Emphasis is on the use of chemically safe materials, clean water, renewable energy and social standards during production. Meanwhile, Recyclabs uses a chemical procedure to return previously non-recyclable plastic waste to the technical cycle. Their approach qualified for the Calls for Transfer funding scheme in 2023 after scooping the 2022 Hamburg Innovation Award. Mechanically non-recyclable polyethylene terephthalate plastic waste (PET) is broken down into individual building blocks and then converted into new, high-purity PET.

Lignopure biotech start-up

The circular economy is based on reusing and regenerating materials and products for as long as possible, ultimately reducing waste. Yet, waste is valuable. The biotech start-up Lignopure, a spin-off from the Technical University of Hamburg, focuses on the natural raw material lignin, a by-product of bio-refineries in the paper and pulp industry. Its patented technology transforms this waste into an ingredient for cosmetics, e.g., with antioxidant and UV protection properties and returns it to the production cycle instead of incinerating it.

Wildplastic & Traceless

The Hamburg-based start-up Wildplastic managed by Christian Siegmund produces bin liners and packaging made from so-called wild plastic collected in countries without recycling infrastructure. This approach won over the Hamburg-based Otto Group in 2022 after packing around half of its goods in the material supplied by Wildplastic and breaking the 100 per cent mark in early 2024. Meanwhile, the bioeconomy start-up, Traceless, which focuses on plant-based plastic substitutes, announced yet another success story in June. The company already works with Lufthansa, C&A and Otto and has now forged a collaboration with the Mondi packaging and paper manufacturer to use fully compostable material for paper coating. After raising EUR 36.6 million in a Series A funding round, Traceless has begun building a large factory in Hamburgto further develop its technology. The German Ministry for the Environment, Nature Conservation, Nuclear Safety and Consumer Protection has earmarked EUR 5 million in funds for the project. Whatever the reasons, the city’s plastic waste statistics are heading in the right direction after the volume of plastic was halved from 740 tonnes in 2019 to 328 tonnes in 2022.

ys/pb

Sources and further information

More

Similar articles

Hamburg coming up with solutions to menace of plastic

Corporate initiative "Plastic-Free City" launches in Hamburg