Various maritime players have formed the co-operative MN3D network funded by the German Ministry of Economics. This comes against the backdrop of the Maritime Cluster Northern Germany's (MCN) push towards greater digitalisation and especially 3D printing as a strategic focal point. Global sales in additive manufacturing with software, hardware and materials increased by 18 per cent to over EUR 8 billion in 2018, according to MCN. The 3D printing market is likely to grow rapidly in the coming years. While additive manufacturing methods are already established in the automotive and aerospace industries, their use in the maritime sector is still in its infancy.

Search for innovative solutions

"The Maritime Network for 3D Printing (MN3D) aims to develop processes and products that better address the specific challenges in the maritime industry," said Daniel Klose, Network Manager at DSN Connecting Knowledge. "These concern the size of the components and their exposure to low-frequency vibrations and seawater, their accessibility, durability and reliability. They have to meet environmental requirements and prove their economic efficiency. All this requires innovative solutions that differ from additive manufacturing in other sectors."

Plans and events

MN3D will develop a technological roadmap for this purpose. Plans are being laid for R&D projects in the sub-areas of surface quality, materials, integration of sensor technology, component sizes and tool life. The network is funded by the German Ministry of Economics and Technology through the Central Innovation Programme for SMEs (ZIM) to enable such companies to conduct R&D projects with research institutions. The network will also attend the world's leading maritime trade fair SMM 2021 in Hamburg. Members will showcase their latest products and processes In the "Maritime 3D-Printing Show Area" from February 2 to 5, 2021.

Participants

A total of 20 companies and research Institutes including members of MCN from all over northern Germany have formed the network. Members of MCN including Winter 3D-Konstruktions GmbH, DNV GL SE, FEM-composites, Gebr. Friedrich Kiel, Gebr. Potthast Plastic Coating GmbH & Co. KG, MMG, Reintjes Powertrain Solutions GmbH, Rolf Lenk Werkzeug- und Maschinenbau GmbH, S.M.I.L.E-FEM GmbH, Treo GmbH, Weihe GmbH are also partners to the MN3D-network. The Helmholtz-Zentrum Geesthacht Centre for Materials and Coastal Research, University of Applied Sciences (HAW Hamburg) and the Maritimes Zentrum Hochschule Flensburg University of Applied Sciences are members of MCN and participate as research partners.

"We and our members have been active in the field of additive manufacturing for several years," said Lina Harms, Manager of the Maritime Cluster Northern Germany in Hamburg. "SMEs in Germany especially hold great potential for innovation. We would like to support this even further and increase their international competitiveness."

kk/pb

Sources and further information

More

Similar articles

Hamburg's creative hit on new ways of tackling crisis

Dual university HSBA tops CHE Ranking 2020

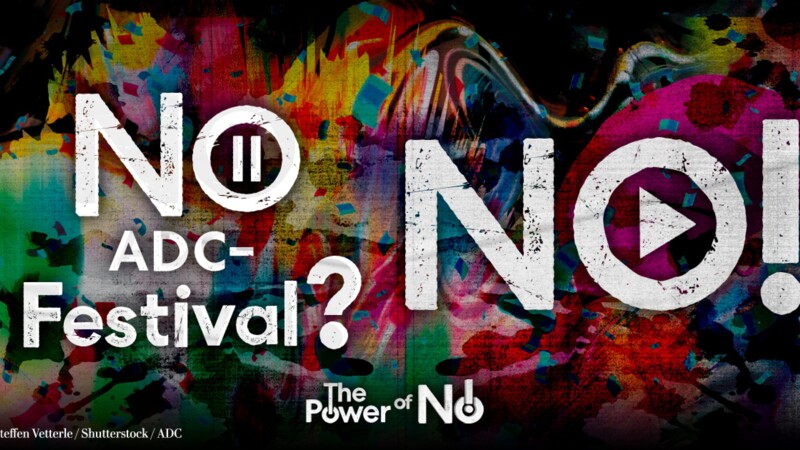

ADC Festival 2020 focuses on "Power of No"