“This research project has shown that the automation of pin handling in rail processing is technically feasible," said Pablo Rossio, HHLA's Project Manager. At the moment, pins are handled manually before loading. This could be done by an autonomous system controlled by HHLA Sky in future. "The robot receives data from the control centre, navigates autonomously along the train and moves the pins it has identified with the aid of a magnetic picker arm. Initially, the system components were simulated and later tested on a demonstrator in the lab," said Johann Bergmann, Team Leader Port Technologies at CML. "Of particular note is the seamless integration of standardized hardware with a Robot Operating System (ROS)-based software architecture, specifically designed to meet the unique requirements of this process,” he added.

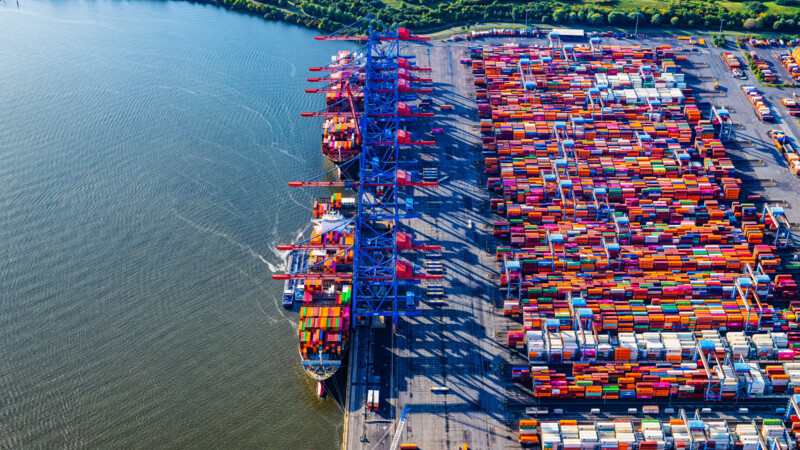

Tests of a mobile robot that automates the manual repositioning of pins on container trains were recently undertaken in real-life conditions in the HHLA Container Terminal Tollerort (CTT), a press release said Tuesday (April 2, 2025). The tests are part of the successfully concluded “Pin-Handling-mR" project by Hamburger Hafen und Logistik AG (HHLA) and the Fraunhofer Centre for Maritime Logistics and Services (CML).

Automated pin handling technically feasible

More efficient, secure terminal procedures

Although the system is not yet ready to go into production, the research project has laid the foundations for its further development. "Thanks to the group-wide network established for the project – spanning our container terminals, HHLA Sky, and our rail subsidiary Metrans – we have combined our expertise to make terminal processes safer and more efficient. In the next phase, we aim to further develop this technology to enable its application in productive operations,” Rossio added.

HHLA coordinated the project, backed by its subsidiaries HHLA Container Terminal Tollerort, HHLA Sky, Hamburg Port Consulting (HPC) and Metrans. Designed and developed by the Fraunhofer CML, the research project was funded by the German Ministry for Digital and Transport as part of the Innovative Port Technologies (IHATEC) funding scheme.

mm/sb/pb