Vishay is on course for growth with rising demand for its silicon wafers on which microchips are manufactured. Hopes are now high that the second factory, the shell of which is due for completion in late 2023, will alleviate capacity difficulties. Leif Henningsen, Managing Director of Vishay Siliconix Itzehoe GmbH, commented: "Here in Itzehoe, we are proud to be making Europe less dependent on producers in other parts of the world and vulnerable supply chains." Tilo Bormann, Head of Wafer Production, added: "We will not let short-term fluctuations in the semiconductor market dissuade us from pursuing long-term strategies. The automotive industry will continue to rely on our technologies in future."

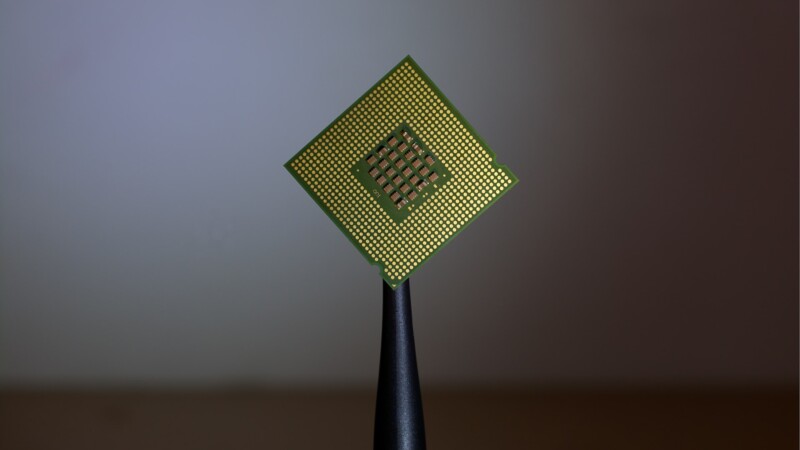

Vishay building new chip factory in Hamburg Metropolitan Region

The U.S. semiconductor group Vishay has begun building a new chip factory in Itzehoe at a cost of USD 400 million (EUR 372 million) and creating 150 new jobs. Company representatives as well as politicians and business people attended the groundbreaking ceremony on Monday (March 20, 2023) for the new factory which is expected to double production from 2025. This comes as the group’s existing factory reaches its limits

More independent production

300-millimetre wafers for automotive industry

Vishay’s wafers, which have been produced in Itzehoe since 2015, are installed in mobile phones and cars. The new factory should secure the jobs of 500 employeesat present. The search is now underway for another 150 employees to produce 300-millimetre wafers. The investment in the factory in the Hamburg Metropolitan region is one of the largest in Vishay’s history with first deliveries expected from early 2026.

nj/sb/pb

Sources and further information

More

Similar articles

Vishay investing EUR 300 million in Hamburg Metropolitan Region

Customcells - premium battery cells "Made in Germany"