The Internet of Things (IoT) is a central component of digitisation. Especially in industry, the potential of IoT applications is immense, ranging from autonomous production and predictive maintenance to real-time logistics. This technology is paving the way for the intelligent factory of tomorrow, as the smart interconnection of machines, people and products forms the basis for the smart factory. Smart production is therefore at the centre of Industry 4.0, which experts refer to as the fourth industrial revolution. In Hamburg, a traditional centre of industry, established companies and innovative startups are dedicated to developing innovative IoT solutions.

How Hamburg is driving Industry 4.0 forward

Smart factory in Hamburg

Study: One in four machines is already smart

The fourth industrial revolution is taking shape: three out of four companies in Germany are on their way to Industry 4.0, according to a study (2019) by Bitkom e. V. On average, one in four machines (25%) in the German manufacturing industry is connected to the internet. In every tenth company, more than 50% of the machines are connected to the internet. As an industrial centre, Hamburg identified Industry 4.0 as a digital field of action back in 2017 and anchored it in the Industry Master Plan. This was initiated by the City of Hamburg, the Industrieverband Hamburg e. V. (IVH) and the Hamburg Chamber of Commerce (HK).

Nortec conference and competence centre

Once a year, Hamburg's exhibition grounds become the industry meeting place for trade visitors interested in all aspects of modern production. Hosted by Hamburg Messe und Congress GmbH, the Nortec trade fair showcases the latest technical developments and solutions for Industry 4.0 with more than 400 exhibitors. In addition, the topic of digitisation plays a special role at the Mittelstand 4.0-Competence Centre Hamburg. Based at the Hamburg Chamber of Commerce, the centre also promotes the Internet of Things and Industry 4.0 as part of regular events.

Man and machine hand in hand

According to a study by IDG Research, one of the most common arguments against large-scale IoT activities in German companies are "concerns about privacy and safety". And this is precisely what startup such as Cybus aim to address: founded in Hamburg in 2015, the tech company has developed software designed to protect sensitive data in the digital factory. In addition to interconnected production facilities and real-time communication between machines, the smart factory also includes support from robots.

To make production as efficient as possible, Synergeticon, another Hamburg-based startup, is teaching robots how to multitask: "The robot scans its environment with a multi-level sensor system. First, just roughly for orientation, and, in a second step, in more detail to solve specific tasks. The system is comparable to that of self-driving cars," explains Synergeticon co-founder Daniel Erdelmeier. In future, these robots could take on physically strenuous and monotonous tasks in particular.

The cleantech startup Breeze Technologies uses IoT sensors to generate local climate and air quality data - very much in the spirit of the smart city. The company is based in Hamburg and was recognised as one of the European Union's most promising startups in 2018.

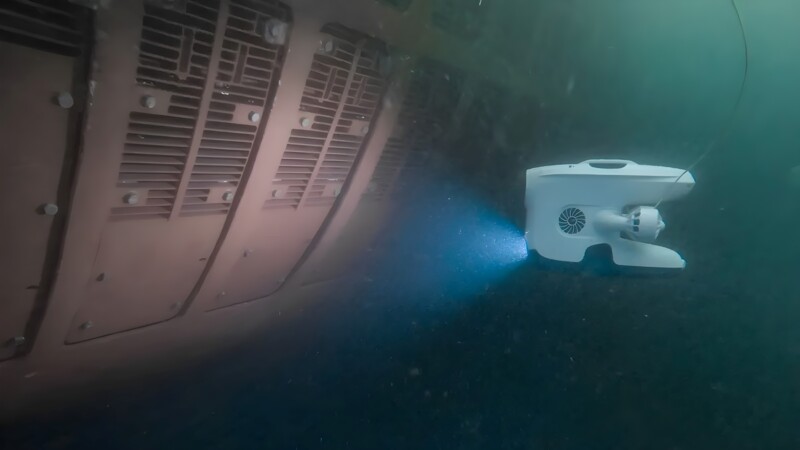

Internet of Things in the port of Hamburg

As part of the Smart Port programme, the Hamburg Port Authority (HPA) is testing various technologies, including the Internet of Things. The 'Port Traffic Centre' is intended to explore ways of centrally controlling the three modes of transport - water, road and rail - in the port of Hamburg. In this context, the traffic situation in the port and waterways will be analysed with the help of IoT sensors. Moreover, in the St Pauli neighbourhood there is a "tech playground" that allows companies and other interested parties to experience disruptive key technologies such as the Internet of Things, as well as robotics and AI.

What is the Internet of Things?

The Internet of Things (IoT) is a network of physical objects (e.g. vehicles, machines, household appliances) equipped with sensors and interfaces that are connected to the internet and exchange data. The IoT thus creates the communication basis for the smart factory. The term "intelligent factory" refers to highly automated production that functions almost without human intervention. The smart factory is therefore at the centre of Industry 4.0.